- 14-07-2023

- Admin

Mastering the Art of Procurement: Strategies for Streamlined Success

Procurement encompasses a wide range of activities that businesses undertake to acquire goods and services. Although it is commonly associated with the final stage of purchasing, procurement can also encompass the entire process involved in sourcing and acquiring the necessary resources for a company.

Procurement involves both buyer and seller perspectives, although the emphasis is often on the buying organization. In essence, procurement aims to achieve "the five rights": obtaining the appropriate quality, quantity, timing, pricing, and source of goods and services.

In the current business environment, competition is intensifying with numerous top-notch rivals emerging both domestically and internationally. To remain competitive, organizations have been compelled to enhance their internal processes. The presence of numerous competitors and a wide array of options has shaped customer expectations, driving them to seek higher quality, quicker delivery, and personalized products and services that are cost-effective in the long run.

Several factors contribute to the growing importance of optimal procurement strategy, processes, and execution. Some key factors include:

1. Enhanced cost efficiency and improved availability of information resources across the entire supply chain, reducing potential delays in the network.

2. Intense competition in both domestic and international markets, necessitating organizations to be agile, fast, and adaptable.

3. Evolving and increasingly demanding customer expectations and requirements.

4. The ability of an organization's procurement and supply chain to identify and mitigate risks, minimizing disruptions in the supply of goods and downstream products or services, thereby mitigating the impact on lost sales. The need for organizations and their suppliers to be responsive to evolving customer needs in order to capitalize on opportunities and maintain revenue share.

In today's interconnected business landscape, no organization can operate in complete isolation and self-sufficiency. Businesses often rely on external entities to procure goods and services that are vital to their operational needs. It is crucial to recognize that the procurement process goes beyond mere acquisition for day-to-day operations; it encompasses securing long-term value for the company as well.

When considering the broader picture, purchasing decisions are influenced by factors such as delivery time, product quality, inherent value, and competitive pricing. The impact of procurement extends across various functions within a business and any misjudgement can disrupt timelines across multiple processes. Consequently, it becomes crucial for organizations to establish a robust procurement and supply chain management strategy to enhance business benefits, ensure success, and maintain continuity. Hence, procurement can be viewed as a comprehensive strategic approach encompassing the identification, planning, and acquisition of both present and future organizational needs. Assuming strategic responsibilities in procurement becomes pivotal in determining the long-term growth and prosperity of organizations.

.png)

Procurement Excellence: Unveiling the Key Objectives of World-Class Organizations

Before delving into the intricacies of the procurement process, it is important to understand the primary objectives that world-class organizations strive to achieve in relation to procurement.

Objective #1 - Supply Assurance

Procurement plays a vital role in meeting the operational needs of a business by acquiring services, raw materials, and diverse components. Additionally, it supports requirements related to physical distribution efforts, the development of new products/services, and the outsourcing of critical processes.

Procurement carries a significant responsibility as a substantial portion of key business processes relies on suppliers. It is crucial for procurement to ensure a consistent and uninterrupted supply of high-quality goods and services. Supply assurance plays a critical role in this context, as any absence thereof may result in an increase in maverick buying.

Objective #2 - Effective Management of Procurement Process

Organizations employ various strategies to efficiently manage their procurement processes, including assessing staffing requirements, strictly adhering to administrative budgets, and ensuring the workforce is equipped to meet both current and future procurement needs.

Implementing enhanced buying channels within procure-to-pay systems offers several advantages to organizations, including enhanced spending visibility, streamlined invoicing and payment processes, and improved user satisfaction.

Procurement teams should prioritize continual improvement of transactional-level work by implementing efficient purchasing systems that facilitate the management of relationships and performance across multiple stakeholders.

Talent management has become a critical responsibility for procurement, considering the increasing global demand for qualified purchasing professionals due to the significant expansion of organizations' production boundaries.

Objective #3 - Supplier Performance Management

In the present-day business landscape, effective procurement necessitates the implementation of supplier performance management (SPM), which entails the careful selection, development, and maintenance of suppliers. Robust supplier performance management is vital as it enables procurement teams to efficiently manage relationships with external suppliers and establish dependable sources of high-quality supplies.

Objective #4 - Integrated Supply Strategy Development in Alignment with Business Goals

There are various reasons why supply management may struggle to develop strategies and plans that align with or support organizational strategies, including:

1. Limited involvement of supply personnel in C-suite level business planning throughout history.

2. Inability to fully recognize and capitalize on the potential benefits of implementing best-in-class procurement practices.

The strategy development process takes place on four levels:

• Corporate Strategies: These strategies focus on the procurement and distribution of resources to these business units.

• Business Unit Strategies: These strategies revolve around defining the scope or limitations of each business unit and establishing the connections with the corporate strategy. Additionally, they determine the approach through which the business unit can attain and sustain a competitive advantage within its industry.

• Supply Management Strategies: Functional strategies, including supply management, play a vital role in strategy development. These strategies outline how supply management will (1) support the desired competitive business-level strategy and synergize with other functional strategies like marketing and operations.

• Category/Sourcing Strategies: These strategies provide a framework for a group responsible for developing the strategy for a specific purchasing category. They outline the steps and actions needed to achieve goals that will, in turn, support supply management, business unit, and ultimately corporate-level strategies.

Businesses must recognize the importance of viewing their procurement personnel not only as technical support but also as crucial catalysts in the decision-making process. It is essential to actively seek the opinions of procurement personnel on supply market intelligence, budget forecasts, and other valuable insights to drive highly strategic business planning.

Unlocking Success: How a Streamlined Procurement Process Boosts Business Performance

Organizations are increasingly recognizing the influential role procurement plays in streamlining operations and driving high-growth and revenue goals. They understand that effective procurement is crucial for attaining a competitive advantage. There are various additional advantages that can be gained by streamlining the procurement process:

• Cost Optimization

The procurement department's main objective is to secure suitable suppliers at competitive prices. The company can evaluate potential suppliers from various business perspectives and select the one that offers the most favourable business benefits. This tactical approach allows companies to negotiate discounts and warranties that may be overlooked by non-specialists. Overall, it entails ensuring timely delivery of orders and fair pricing from the chosen supplier.

• Stakeholder Management

Effective stakeholder management is a critical element of procurement, encompassing both internal and external stakeholders. Internal stakeholders consist of budget owners, finance and legal departments, and senior management within the organization. External stakeholders encompass vendors, suppliers, and other parties that play a vital role in the procurement process. Nurturing positive relationships with these stakeholders is imperative for ensuring long-term success.

Organizations are increasingly aiming to outsource a greater portion of parts, components, and services to focus on their core areas of specialization and expertise. As a result, effectively managing and nurturing relationships among stakeholders becomes even more crucial.

• Drives Innovation

The procurement department of an enterprise possesses the potential to be a catalyst for organization-wide innovation. This can be achieved through supplier selection that promotes innovation, exploring novel approaches to create value for the business, and effectively coordinating between internal and external stakeholders. These efforts play a crucial role in aligning business processes towards fostering innovation.

• Enhances Customer Value

Organizations have long prioritized customer satisfaction, recognizing that the quality of products and services directly impacts their customers' experience. By procuring the appropriate raw materials and necessary services from trusted suppliers, organizations can ensure that their customers receive optimal value for their investment.

• Enhancing the Speed to Market

In today's business landscape, the time to market is a critical key performance indicator (KPI) for organizations as it determines their ability to capture the attention of their target audiences amidst intense competition. Products and services that are delayed in reaching the market may struggle to make the desired impact, leading to tangible and intangible consequences for the organization.

Procurement, serving as the bridge between suppliers and organizations, holds a crucial position in accelerating product development efforts. Research has shown that companies that engage suppliers in the early stages of development achieve an average improvement of 20 percent in areas such as materials costs, material quality, and product development timelines when compared to companies that do not involve suppliers. Incorporating the suppliers' perspective can be valuable for organizations as it allows them to gather improvement suggestions. By adopting the appropriate procurement strategy and fostering collaboration with suppliers, organizations can leverage their expertise to add new value and enhance competitiveness.

• Managing Supplier Risk

While every business process carries a certain level of risk, the risk significantly escalates when an organization relies on suppliers located in different geographical locations.

The risks associated with supplier dependencies can vary in severity, ranging from major to minor. Sourcing strategies that prioritize global sourcing, single sourcing, and just-in-time (JIT) inventory further amplify these risks. Implementing a strong procurement process and strategy is crucial in mitigating and managing these additional risks. Organizations can rely on their procurement teams to proactively monitor the supply base for potential risks and develop effective business continuity plans to mitigate and address these risks.

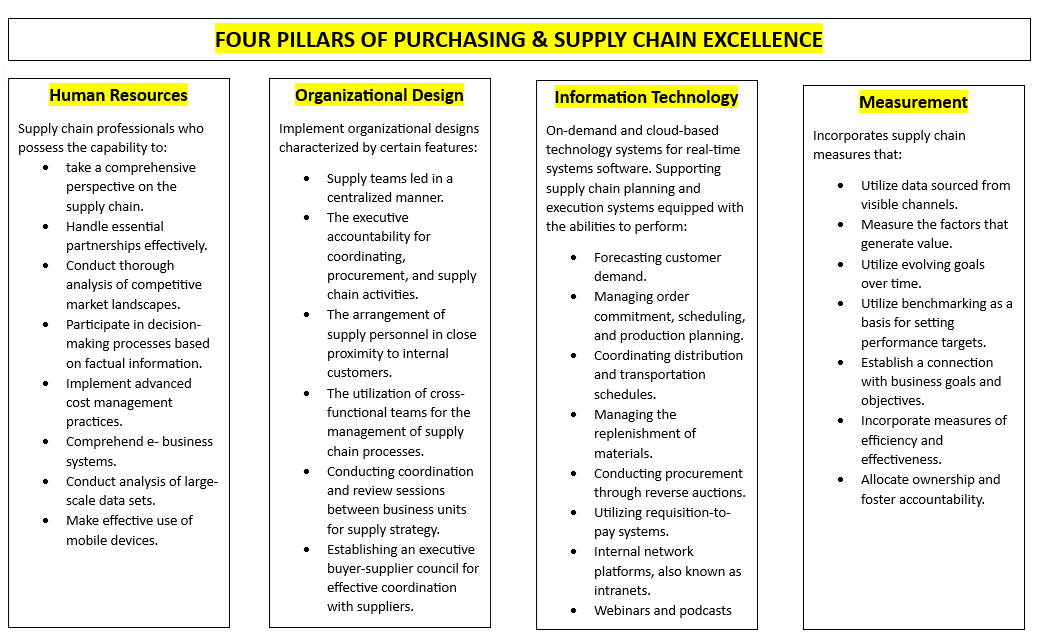

Procurement enablers offer support to organizations, facilitating the development of innovative strategies and approaches. According to the four enablers model, organizations have fundamental guiding principles and prerequisites that serve as the basis for all their supply chain activities. These guiding philosophies and requirements primarily focus on areas such as globalization, customer responsiveness, and supply chain integration. Procurement enablers, in turn, provide the necessary support to develop strategies and approaches that align with these philosophies and requirements, while also contributing to the achievement of purchasing, supply chain, and organizational objectives and strategies.

Unlocking Success: The Power of Capable Human Resources in Procurement

The quality of employees plays a pivotal role in determining the success of any company, and this holds especially true for the field of purchasing. According to previous research, the five essential knowledge areas for purchasers are as follows: (1) managing supplier relationships, (2) conducting total cost analysis, (3) formulating purchasing strategies, (4) performing supplier analysis, and (5) conducting competitive market analysis.

Successful supply chain management necessitates extensive collaboration with suppliers, as well as internal coordination among engineering, procurement, logistics, customers, and marketing teams. This collaborative effort aims to synchronize activities and material flows throughout the supply chain. Establishing strong relationships with key suppliers serves as the foundation for developing effective purchasing strategies.

Cost management has evolved into a crucial aspect of purchasing and supply chain management. In the face of customer price constraints, effectively managing costs has become vital for achieving long-term success. At a prominent U.S. chemical company, purchasing specialists employ total cost models to assess significant supply decisions, leveraging data from suppliers and various sources. Similarly, another company mandates its teams to identify cost drivers upstream, extending beyond immediate suppliers, and subsequently focus on enhancing those areas. By combining comprehensive cost analyses with market conditions and evaluations of supplier capabilities, an encompassing purchasing strategy is formulated.

Reimagining Success: The Impact of Proper Organizational Design

Organizational design encompasses the evaluation and selection of an appropriate structure and formal system that governs communication, division of labour, coordination, control, authority, and responsibility within an organization. This process is crucial in aligning with the overall organizational goals and objectives, including those related to the supply chain. It's important to note that formal organizational charts only provide a limited representation of an organization's functioning. As an example, centre-led supply management structures have gained popularity and are being adopted by many organizations to streamline and optimize their supply management practices.

Hybrid organizational forms incorporate diverse coordinating mechanisms that extend beyond the confines of a formal organizational chart. While the utilization of teams in supply chain design remains crucial, it is essential for managers to exercise selective discretion in their implementation. Despite the significance of teams, the correlation between teaming and enhanced performance lacks extensive empirical evidence, with only a limited number of studies quantitatively evaluating the impact of teaming on overall corporate performance. Therefore, incorporating organizational work teams to support purchasing and supply chain objectives does not automatically ensure increased effectiveness.

Revolutionizing Collaboration: Unleashing the Power of Real-Time Technology

In the twenty-first century, the advancement of information technology (IT) has witnessed rapid growth, particularly in the development of software and platforms that facilitate end-to-end supply chain management. This progress encompasses the emergence of cloud-based storage systems, the advent of mobile devices enabling visual meetings through platforms like Skype, and the availability of shared software platforms that promote visibility and collaboration among supply chain partners of all sizes. Additionally, identification technologies like radio frequency identification (RFID) and voice recognition systems have continuously improved, enhancing their capabilities and effectiveness.

Supply chain systems should be able to collect and exchange information seamlessly among different departments and organizations, regardless of the specific technology platform or software employed. This information sharing should ideally occur in real-time or near-real-time. It may entail the utilization of global positioning systems (GPS) to track the location of transportation vehicles, internet-based systems to transmit material requirements to suppliers, or barcode technology to monitor the punctuality of supplier deliveries. Increasingly, RFID tags are being adopted in various applications to capture immediate data regarding the movement of materials and products throughout the supply chain.

Unveiling the Metrics: Unleashing the Potential of Procurement Measurement Systems

Measurement systems play a crucial role as the fourth pillar supporting purchasing and supply chain excellence. However, several obstacles hinder the translation of measurement into improved performance. These roadblocks encompass

(1) an excessive number of metrics,

(2) debates surrounding the selection of appropriate metrics,

(3) the constant evolution of metrics, and

(4) reliance on outdated data.

To overcome these challenges, organizations must clearly define what they intend to measure, establish a robust measurement process, and ensure access to accurate and relevant data. Subsequently, it becomes imperative to take proactive steps based on the insights gained from the measurement data. Lastly, like any planning system, targets should be periodically revised to align with market realities, competitive landscape, and evolving organizational goals.

Measurement holds significant importance for several reasons. Firstly, objective measurement enables decision-making based on factual information rather than subjective judgments. This promotes a more reliable and accurate approach to decision-making in supply chain management.

Secondly, measurement serves as an effective means to communicate requirements to other stakeholders within the supply chain. It fosters clear expectations and facilitates continuous improvement and change initiatives. When suppliers are aware that their performance is being monitored, they are incentivized to enhance their performance levels.

Furthermore, measurement systems are utilized not only to improve future supplier performance but also to recognize exceptional performance. By measuring supplier performance, organizations can identify areas of excellence and acknowledge suppliers who consistently meet or exceed expectations.

Additionally, the measurement process plays a crucial role in evaluating the effectiveness of new initiatives. It helps determine whether implemented changes and strategies are yielding the desired outcomes, allowing for necessary adjustments and improvements.

Lastly, measurement serves as a powerful tool for controlling and managing purchasing and supply chain activities and processes. It provides valuable insights into the performance of various functions, enabling organizations to identify areas for improvement, track progress, and make informed decisions to optimize overall performance.

Overall, measurement serves as a critical mechanism for enhancing decision-making, promoting improvement, incentivizing performance, evaluating initiatives, and controlling supply chain activities.

The pursuit of purchasing and supply chain excellence relies on four key enablers that help shape progressive approaches and strategies. Neglecting these enablers can hinder organizations from developing innovative practices and approaches, leaving them at a disadvantage compared to competitors who prioritize these areas. By emphasizing and prioritizing these enablers, organizations can better position themselves to achieve and maintain excellence in purchasing and supply chain management.

Get in touch with us for all your procurement requirements and let us cater to your needs with our expertise.

Recent Blogs

COMPRESSOR SPARE PARTS AND OIL PRICE LIST

GENERAL PUMPS PRICE LIST

Navigating International Trade with Letter of Credit (LC): The Key to Smooth Transactions

Maximize Profits and Minimize Costs: A Guide to Winning Supplier Negotiations